Products

Moulded pulp is a sustainable packaging material made

from a blend of recycled paper, cardboard, or other plant-based

fibers. It’s created through a process that involves

shredding and mixing these fibers with water to create a pulp.

This pulp is then moulded into specific shapes and forms

using moulds, which are then dried and hardened to create

the final packaging product.

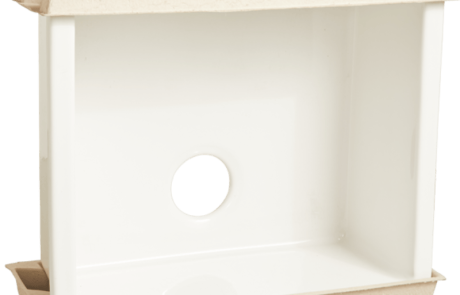

The process of moulding pulp allows for the creation of a diverse range of packaging solutions, from protective trays and cushioning materials to intricate designs that can fit the contours of various products.

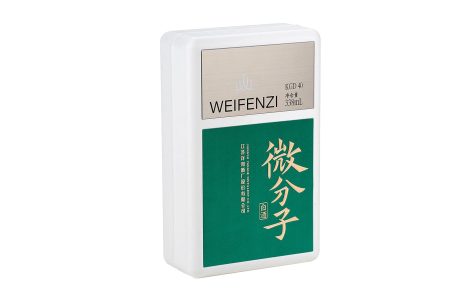

Its versatility in shape and structure makes it an excellent choice for packaging items of different sizes and shapes, including fragile or delicate products like electronics, glassware, cosmetics, and more.

Different raw material recipes define the final colour of the packaging, which can vary from brown, grey to white or any other colours if using special inks.

Different production proceses define the final smoothness of the products. Whether your product is for B2B or B2C segment, we can help you to define your optimal packaging.

View some of our products

What is good to know when orderding packaging?

It’s essential to understand that the quality of this packaging – its color, processing finesse, and appearance – greatly depends on the individual manufacturer.

We specialize in tailoring packaging solutions to fit your product specifications, ensuring a perfect fit and maximum protection. Our packaging solutions are available in various colors, finishes, sizes and covering a wide range of general and specific customer requirements.

Key characteristics of moulded pulp for

sustainable packaging include

Environmental sustainability

Moulded pulp is eco-friendly as it is predominantly made from recycled materials, often post-consumer paper waste. This makes it biodegradable, compostable, and recyclable, reducing the environmental impact of packaging materials.

Protection and cushioning

Despite its eco-friendly nature, moulded pulp offers excellent protective properties. Its inherent cushioning abilities make it ideal for safeguarding products during transportation and storage, absorbing shocks and vibrations that could potentially damage goods.

Customizability

Moulded pulp can be tailored to fit specific product shapes and sizes. It allows for customization, ensuring a snug fit that securely holds the product in place while providing adequate protection.

Adaptability and versatility

The material can be designed in various forms, from simple shapes to complex structures, allowing for a wide range of applications across different industries.

Biodegradability and recyclability

Due to its composition of natural fibers, mou lded pulp breaks down easily when discarded, contributing to a circular economy by reducing waste and being recyclable or compostable in appropriate facilities.

Proximity to expert packaging counselors

Our proficient sales representatives, stationed across various countries, stand poised to provide you with expert guidance and advices.

Highly competitive prices

Our premium, eco-friendly packaging solutions are offered to you at highly competitive and favorable price points.

Rapid prototyping and timely delivery of sample batches

Tailored offerings aligned with your requirements, spanning product size, geographic location, and preference for just-in-time deliveries.