Styrofoam worked for years.

It was cheap. Light. Easy to source. Easy to explain.

And, for a long time, nobody questioned it.

Until they did.

If you are responsible for packaging decisions in your company, you have probably noticed the shift already.

Customers ask what happens after the product is unpacked. Buyers want proof, not Claims. Waste fees quietly rise. Regulations stop being »something for later«.

At some point, plastic stops being a safe choice.

Switching materials sounds risky. Especially if you ship fragile products and high volumes. But the transition does not have to be chaotic. We see it every day.

Read on to see how a typical switch from plastic to moulded pulp actually happens.

Step 1: Here, we define the problem, not the material.

Most companies contact us and start with a similar sentence:

»We need a plastic-free solution. That offers the same protection. And a stable supply. «

We at Tricor d.o.o. take a look at the product:

- Its shape and dimensions.

- Its fragile edges.

- Its pressure points.

- We check where the product needs to be held.

- And just as important, where it must never touch the tray.

This step is often underestimated. But moulded pulp packaging works best when it is designed around the product, not forced to replace plastic one to one.

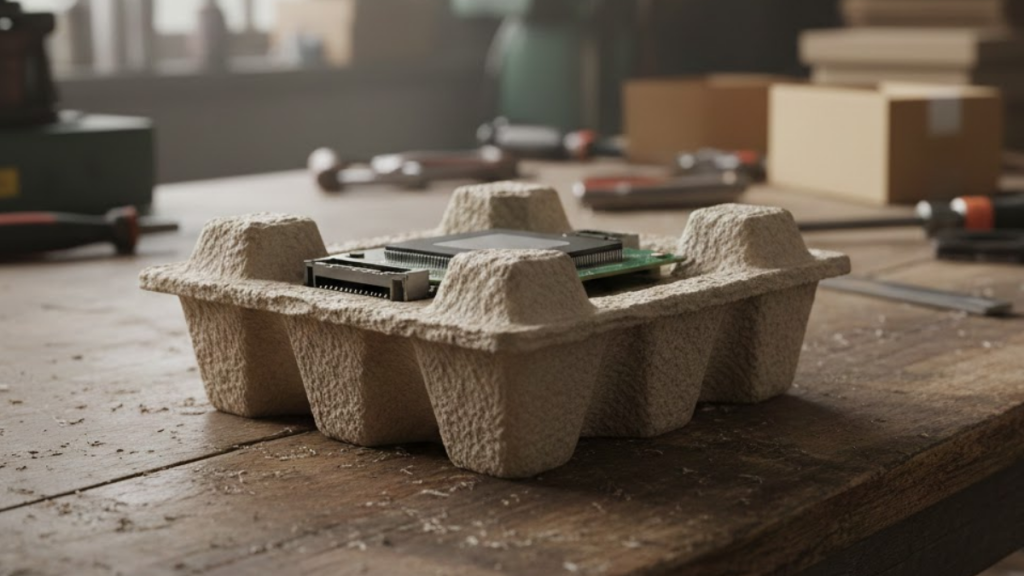

Example: a mid sized electronics manufacture that is shipping thousands of units per week. Fragile components. Tight logistics. No room for guesswork.

The goal is not “eco packaging#.

It’s no damage, no supply issues and no surprises.

Step 2: Design, touch, adjust.

Once the product is fully understood, the tray design begins.

First, a 3D draft.

Geometry, support points, tolerances.

We review it together with the client.

Adjustments are normal. They always happen.

Then comes the important part: physical samples.

Pilot trays are produced using the same fibre logic and forming method as serial production, just on a smaller scale. This matters. It avoids false expectations later.

Then the client puts the product in the tray.

Lifts it, tilts it, feels how it sits.

And at this moment minds are often changed. Moulded pulp stops being an alternative and becomes a real packaging solution.

Step 3: Test, tool, scale.

When the mock-up is approved, the production tool is made.

A metal mould that is built for repetition and volume.

Then follow the first production samples.

We do not assume they work. We test them.

Drop them. Stack them. Transport them.

Minor adjustments are common at this stage. In thickness or support. Then the design is locked and large scale production starts.

This is the point where production is no longer theoretical but operational.

What changes for the client?

Outcome is clear:

- Packaging made from recycled paper waste

- Fully recyclable after use

- Better product stability during transport

- Cleaner warehouse handling

- Faster packing process

- Stronger position in buyer conversations

And something else too. Something rarely shown in reports. It’s the fact that people on the team feel better about shipping the product. That actually matters more than many companies care to admit.

In 2026 packaging isn’t going to be invisible anymore.

It will be inspected.

Measured.

Questioned.

Choosing moulded pulp packaging is not idealism. It’s control

With this in mind, packaging is not a marketing decision. It is a business one.

If you are considering a move away from plastic, a short conversation is often enough to see if moulded pulp fits your product.

FAQ

Is moulded pulp packaging suitable for fragile products?

Yes. With proper design, moulded pulp can protect delicate electronics and components by supporting pressure points and avoiding contact where it matters.

Is moulded pulp really recyclable?

Standard moulded pulp packaging made from paper fibres is recyclable and biodegradable after use.

How long does the transition take?

From first discussion to serial production, it usually takes a few months, depending on product complexity.

Is it more expensive than plastic?

Tooling costs exist, but many companies balance this with lower waste fees, logistics efficiency, and reduced damage.

Can moulded pulp be customized?

Yes. Shape, structure and branding options can be adapted to the product handling needs.